Seoyon E-Hwa Receives First New Excellent Technology (NET) Certificati…

작성일 25-06-11 11:46

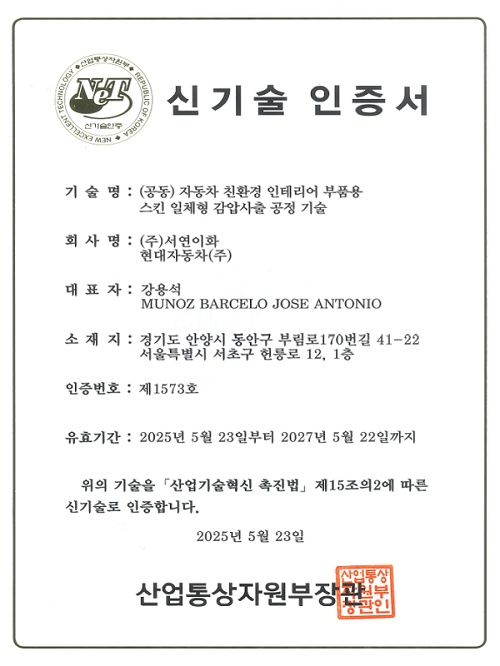

The Skin-Integrated Low-Pressure Injection Molding Technology for Eco-Friendly Automotive Interior Parts, jointly developed by Seoyon E-Hwa and Hyundai Motor Company, has been awarded the first New Excellent Technology (NET) certification of 2025. This certification, overseen by the Korea Industrial Technology Association under the Ministry of Trade, Industry and Energy, is granted by the Korean government to technologies that are either the first of their kind developed domestically or that significantly improve upon existing technologies in terms of innovation and excellence.

The skin-integrated low-pressure injection molding technology addresses a long-standing issue in the fabric insert molding process—foam degradation that reduces cushioning performance. By incorporating a vacuum system inside the mold, this technology enables partial recovery of the foam after injection, achieving cushioning performance on par with insert mold graining (IMG) methods. Furthermore, by bonding the fabric and base material without adhesives, the product becomes self-recyclable. These improvements in quality, coupled with the process’s environmentally friendly nature, have earned recognition for both sustainability and innovation.

This technology also offers an effective solution to meet the European Union’s ELV (End of Life Vehicle) regulations, which mandate that by 2030, 25% of automotive parts must be made from recycled materials—and of that, 25% must come from end-of-life vehicle plastics. As a Tier-1 supplier to global automotive OEMs, Seoyon E-Hwa continues to identify and develop advanced technologies that not only meet customer needs but also ensure competitiveness and sustainability in the face of evolving global regulations.